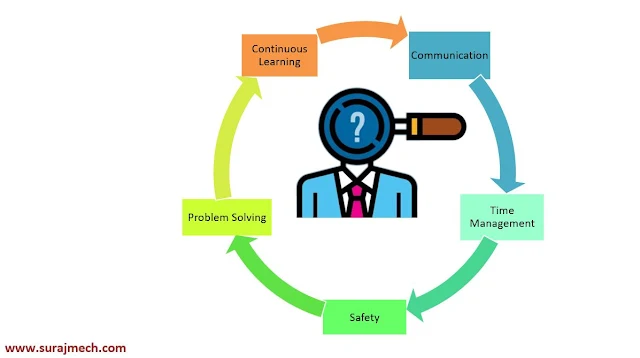

The manufacturing industry plays a vital role in the global economy, and as technology advances, the demand for skilled workers in this sector continues to grow. While technical Knowledge and expertise are crucial for manufacturing success, for example, in hire laravel developer for your project, their technical skills will help you accomplish the task. So, Knowledge of skilled workers must aspiring professionals should possess several essential skills. This article will explore ten skills individuals entering the manufacturing industry need to thrive.

1. Strong Problem-Solving Abilities

Manufacturing environments often present complex challenges that require quick thinking and effective problem-solving skills. Employees must be adept at analyzing situations, identifying root causes, and implementing appropriate solutions. Problem-solving skills enable individuals to troubleshoot issues efficiently, reduce downtime, and improve overall productivity.

- Problem-solving skills are crucial in manufacturing environments.

- They help employees analyze complex challenges and identify root causes.

- Effective problem-solving leads to efficient troubleshooting and reduced downtime.

- It improves overall productivity in manufacturing operations.

- Problem-solving skills contribute to continuous improvement and adaptability.

- Employees with these skills make informed decisions and collaborate effectively.

- Training and development programs enhance problem-solving abilities in the workforce.

2. Attention to Detail

Attention to detail is a critical skill in manufacturing, as even minor errors can have significant consequences. Whether it's in quality control, assembly, or equipment maintenance, precision is crucial. Employees who possess keen attention to detail ensure that products meet specifications, reduce defects, and contribute to a culture of excellence in manufacturing processes.

- Attention to detail is crucial in manufacturing.

- It ensures accuracy and prevents errors with significant consequences.

- Quality control relies on attention to detail for meeting specifications and reducing defects.

- Precise assembly is vital to avoid product malfunction and safety risks.

- Equipment maintenance requires attention to detail to identify issues and optimize performance.

- Attention to detail improves productivity and efficiency by minimizing rework and waste.

- It fosters a culture of excellence, emphasizing accuracy and pride in workmanship.

- It contributes to continuous improvement efforts in manufacturing processes.

- Customer satisfaction relies on meticulous attention to detail in meeting expectations.

- Attention to detail ensures safety compliance and reduces risks in the manufacturing environment.

- Training programs can enhance employees' attention to detail skills.

3. Communication Skills

Effective communication is essential in any industry, and manufacturing is no exception. Clear and concise communication between team members, supervisors, and other departments is vital for maintaining workflow, coordinating tasks, and addressing challenges. Strong communication skills foster collaboration, efficiency, and a positive work environment.

- Effective communication is vital in manufacturing and all industries.

- It maintains workflow and coordination between team members.

- Communication facilitates task coordination and updates across departments.

- Clear communication helps address challenges and resolve issues promptly.

- Strong communication skills foster collaboration and effective problem-solving.

- It improves efficiency, productivity, and overall work performance.

- Good communication creates a positive work environment based on trust and respect.

- Safety protocols and risk-related information are effectively conveyed through communication.

- Customer satisfaction is enhanced through clear communication and addressing concerns.

- Communication enables adaptability to changes in production requirements or technology.

- It supports continuous improvement efforts by sharing insights and ideas.

4. Technical Competence

While this article focuses on non-technical skills, it's important to highlight that technical competence is a fundamental requirement in the manufacturing industry. Proficiency in operating machinery, understanding production processes, and using relevant software and tools are critical for success. Individuals entering the manufacturing field should acquire the necessary technical training and knowledge specific to their roles.

- Technical competence is fundamental in manufacturing.

- Proficiency in machinery operation and production processes is critical.

- Relevant software and tool knowledge is necessary for success.

- Acquiring role-specific technical training is essential.

- Technical competence complements non-technical skills in manufacturing.

5. Adaptability and Flexibility

The manufacturing industry is dynamic and subject to constant changes. Employees must possess adaptability and flexibility to adjust to new technologies, production methods, and market demands. Adaptable individuals are open to learning and embracing change, enabling them to stay ahead of the curve and contribute to the success of their organizations.

- The manufacturing industry is dynamic and constantly evolving.

- Adaptability and flexibility are crucial traits for employees in manufacturing.

- Employees need to adjust to new technologies, production methods, and market demands.

- Adaptable individuals are open to learning and embracing change.

- They stay ahead of the curve and contribute to the success of their organizations.

6. Time Management Skills

In a fast-paced manufacturing environment, time management is crucial. Employees must prioritize tasks, meet deadlines, and optimize workflow efficiency. Effective time management ensures that production processes are streamlined, reducing wastage and maximizing output. Individuals who can manage their time effectively contribute to overall productivity and organizational success.

- Time management is crucial in fast-paced manufacturing.

- Prioritizing tasks and meeting deadlines is essential.

- Effective time management streamlines production and reduces waste.

- It contributes to overall productivity and organizational success.

7. Teamwork and Collaboration

Manufacturing operations often involve teams working together towards a common goal. The ability to collaborate with colleagues, share ideas, and work collectively is essential. Strong teamwork skills foster a supportive work environment, enhance problem-solving capabilities, and improve overall efficiency. Individuals who value teamwork contribute to a harmonious and productive workplace.

- Manufacturing operations require teamwork and collaboration.

- Working together towards a common goal is crucial.

- Strong teamwork skills foster a supportive work environment.

- Collaboration enhances problem-solving capabilities.

- Teamwork improves overall efficiency in manufacturing.

- Valuing teamwork contributes to a harmonious workplace.

- Individuals who collaborate well enhance productivity in manufacturing.

8. Continuous Learning Mindset

The manufacturing industry evolves rapidly due to technological advancements and changing market trends. Aspiring professionals need to cultivate a mindset of continuous learning to stay relevant and adapt to new practices. Seeking opportunities for upskilling, attending training programs, and staying updated on industry developments will ensure long-term success in the manufacturing sector.

- The manufacturing industry evolves rapidly with technology and market trends.

- Continuous learning is essential for professionals in the manufacturing field.

- Cultivating a mindset of continuous learning is crucial for staying relevant.

- Seeking opportunities for upskilling and attending training programs is important.

- Staying updated on industry developments ensures long-term success.

- Adaptability and learning new practices are key in the manufacturing sector.

9. Quality Focus

Manufacturing organizations prioritize quality to deliver products that meet or exceed customer expectations. Employees entering this industry should have a strong focus on quality and take pride in their workmanship. Attention to detail, adherence to standards, and commitment to continuous improvement are crucial for maintaining high-quality standards throughout the production process.

- Quality is a top priority for manufacturing organizations.

- Employees should have a strong focus on quality and take pride in their workmanship.

- Attention to detail is essential for maintaining high-quality standards.

- Adherence to standards ensures consistency and customer satisfaction.

- Commitment to continuous improvement drives ongoing quality enhancements.

- Quality is upheld throughout the entire production process in manufacturing.

10. Safety Awareness

Safety is paramount in manufacturing environments, where potential hazards exist. Individuals must have a keen awareness of safety protocols, follow procedures diligently, and proactively identify and mitigate risks. Prioritizing safety ensures a secure work environment, reduces accidents, and safeguards the well-being of all employees.

- Safety is paramount in manufacturing environments.

- Keen awareness of safety protocols is essential.

- Following procedures diligently is crucial for maintaining safety.

- Proactively identifying and mitigating risks is necessary.

- Prioritizing safety creates a secure work environment.

- It reduces accidents and promotes employee well-being.

- Safety is a shared responsibility in manufacturing.

Post a Comment

Post a Comment

Please do not enter any spam link in the comment box.