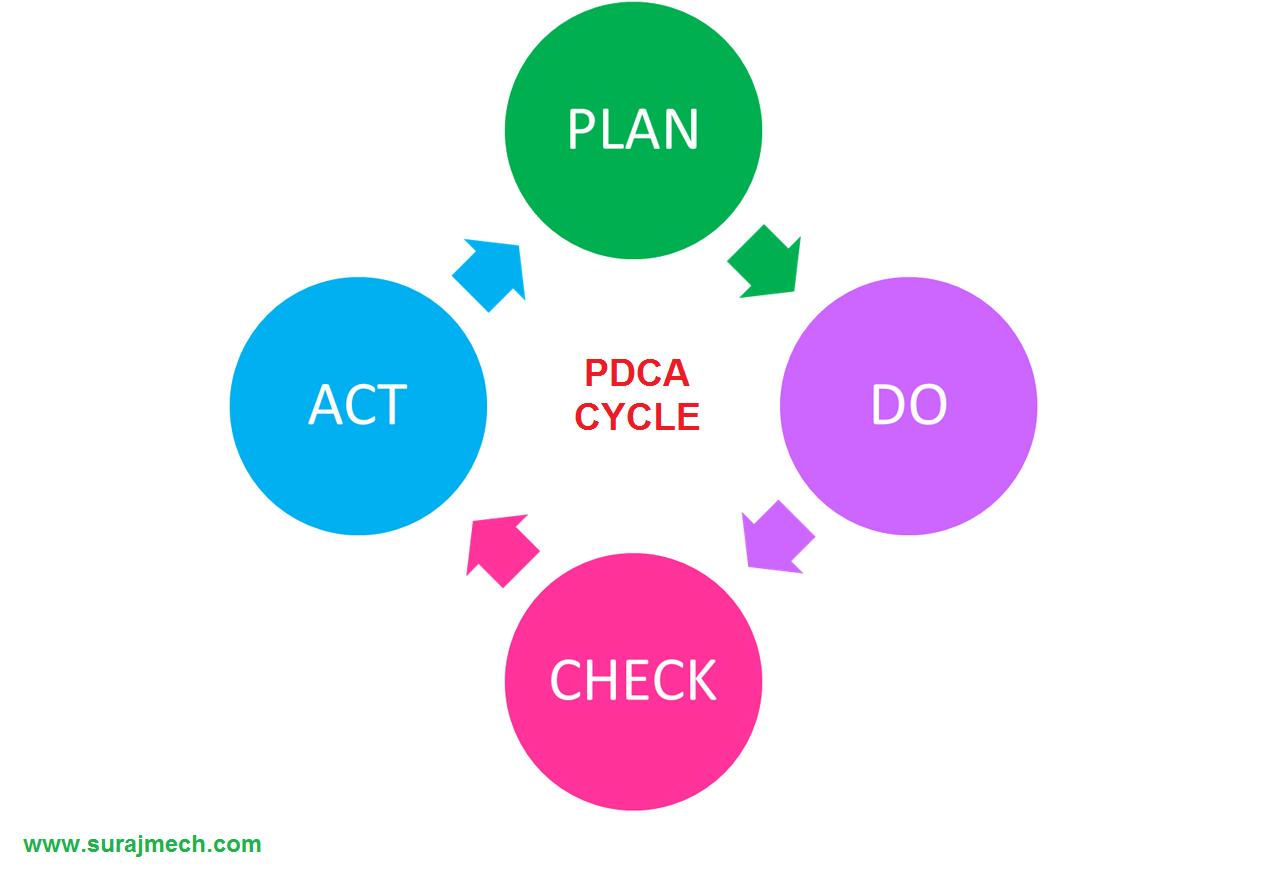

What is PDCA Cycle?

- The Plan-Do-Check-Act (PDCA) Cycle, also known the Deming Cycle, it is a four-step approach to problem-solving that allows you to test various solutions to a problem to find the most effective solution before implementation. The cycle can be refined and repeated time and time again for Continual Process Improvement (CPI) and can be used by any department.

Step One: Plan

- Start by defining the problem and find the root cause using the 5 Whys, a technique developed in the 1930s by Sakichi Toyoda, founder of Toyota Industries that is still used by Toyota today. You may need to take a more in-depth approach (such as Fishbone Diagrams) to find root cause if the issue is overly complex.Example how to use the 5 Whys:

Problem: Your customer received their order two-three weeks later than you promised.

Why? Production was delayed in Germany.

Why? The factory received the shafts they needed two-three weeks later than anticipated.

Why? The shaft supplier did not have the materials ready on time.

Why? They had trouble sourcing the steel needed to make the shafts.

Why? Their sourcing manager is new and inexperienced.

Counter-measure: You need to find a secondary shaft supplier that is reliable.

Remember to base everything on hard facts rather than on assumption. Set SMART goals for every plan. For the above example, your goal could be to qualify a secondary shaft supplier in the Berlin province of Germany within 30 days.

Step Two: Do

- Now that you have defined your problem and found the root cause, it is time to brainstorm to find potential solutions. Once you have your options laid out, determine which you believe will be most practical. Test it out on a small scale (do not fully implement). Think of the “do” phase as the “test” phase.

Example: Continuing the scenario above, you need to find a shaft supplier in Berlin, Germany in the next 30 days. Your office is located in the US. You have identified three options:

1) Find a supplier online,

2) Send your sourcing manager to Germany to find a supplier or

3) Hire a sourcing agent in Germany to find a supplier on your behalf.

You must weigh the costs and risks of each option.

What is your budget?

Which option will allow you to successfully qualify a new supplier in 30 days?

What are your criteria for qualifying the new supplier?

Who will draw up a contract?

Choose the best option for your company.

Step Three: Check

- This step may also be referred to as the “study” phase (as in the Deming Cycle). If you realize there is room for improvement, make necessary changes and repeat the “do” and “check” phases until you feel you have reached a comprehensive solution.

Example: You decided to hire a sourcing agent in Germany to locate and qualify a secondary shaft supplier on your behalf. You need to determine if this was the best option. Did the sourcing agent accomplish the task to your specifications?

Are you satisfied with the amount of money and time spent?

Did anything go wrong? What obstacles had to be overcome?

What factors could you change to improve the process?

Should you have sent your own sourcing manager instead? Would it have been worth the cost?

Step Four: Act

- The final step is to fully implement your solution. If you are solving an isolated issue, congratulations! You are finished. If you are striving for continuous improvement, you should repeat the cycle from Step One: Plan to find additional opportunities for improvement. Lather, rinse, repeat.

Example: Based on your analysis, you have determined that if you need to quickly qualify a secondary supplier in the future, it could be worthwhile to send your sourcing manager to Germany instead of hiring a local agent.Download: PDCA Template

Benefits of Using PDCA

- Provides a standardized method to achieving continuous improvement that can be used by employees in any department to resolve new and recurring issues.

- Prevents wasted time implementing ineffective or inferior solutions.

- Fosters teamwork through brainstorming and problem-solving.

- Inexpensive – Overcome obstacles internally.

- PDCA methodology emphasizes minimizing errors and maximizing outcomes

Tips for Successfully Implementing PDCA

- Upper management must be on-board and treat the Cycle as a mandatory policy for change.

- Remember this is a circular plan, not a one-way plan.

- Implement in all departments of organization.

Post a Comment

Post a Comment

Please do not enter any spam link in the comment box.